S-BACPRO - Achivements

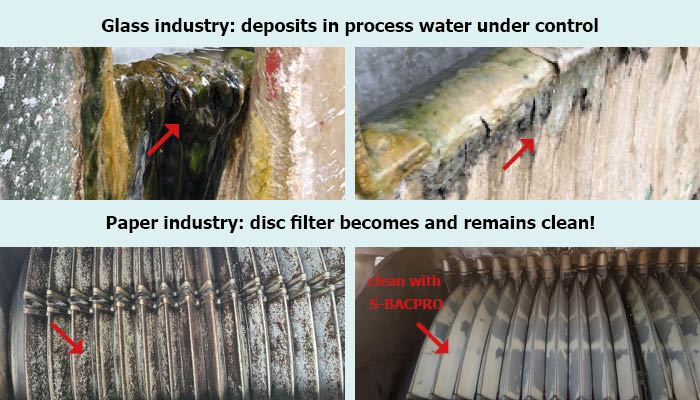

Successful application of S-BACPRO in the glass industry in the cooling tower system

In the glass production process, glass is continuously cooled with cooling water in the area of the scraper belt. This results in the entry of solids, dirt, oils and fats into the cooling system. During stationary operation of the evaporative cooling system, this conglomerate is deposited in the entire cooling system and in the cooling tower tray and leads to increased formation of legionella in the cooling water.

With the continuous dosage of Functional Bacteria (S-BACPRO) we succeeded in reducing organic deposits in a sustainable way. Removing organic deposits, and therefore nutriments, helped reduce Legionella.

Additional positive effect: The consistency of the above mentioned conglomerate became pumpable with the use of S-BACPRO and can be sucked off - before - mining degradation of the sediment layer in the cooling tower basin.

Successful treatment of the disc filter in the paper mill with our Functional Bacteria

The aim was to remove the deposits on the disc filter and keep it clean. We succeeded 100% with the treatment with our Functional Bacteria S-BACPRO.